Hydrostatic Spindles

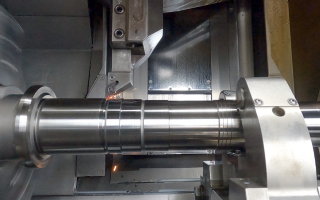

Hydrostatic spindles for high precision grinding, turning and milling

Omlat’s hydrostatic spindles are the ideal solution for machining operations that require maximum precision, stability and rigidity. Each hydrostatic spindle is built on a hydraulic support system that eliminates direct contact between rotating components. This drastically reduces friction, eliminates mechanical wear and ensures exceptionally quiet, smooth performance.

Compared to a conventional spindle, a hydrostatic machine tool spindle offers superior dynamic rigidity, excellent thermal stability and consistent results even at high rotation speeds. These qualities make it an essential component in applications where performance and reliability are critical.</p>

Applications and materials for Omlat hydrostatic spindles

Thanks to their advanced design and performance, Omlat hydrostatic grinding spindles are particularly suitable for high-precision grinding, fine milling and turning operations, especially within the field of high-performance CNC machining. They are designed to maintain tight tolerances and flawless surface finishes, even during continuous operation.

These spindles achieve optimal results when machining materials such as metals, light alloys, technical plastics, glass and composites. The ability to deliver stability and precision on complex or delicate materials makes them ideal for the most demanding industrial contexts.

As one of the leading hydrostatic spindle manufacturers, Omlat offers a wide range of models tailored to the needs of highly specialised sectors, including aerospace, medical technology and precision mould-making.

HYDRO

Hydrostatic grinding spindles, with very high accuracy, low friction, no wear, dynamic rigidity.

Find out More